WP2

The Objectives: |

For more details please refere to the following description. |

The Results: |

|

Participants

AAU-Aal, SDU, DIS

Description

Different methods have been tested and used to dewater lake sediment including geotubes, settling basins, belt filters and belt press. Due to the high content of organic materials and compressibility of lake sediment, low pressure methods are usually used to avoid compression of the sediment as compression will reduce the dewaterability. This results in a low final dry matter content, so a two-step process may be beneficial with filtration at low pressure and consolidation at higher pressure or with a vacuum. To increase the dry matter content, a fundamental understanding of the water in the sediment is required. For sludge four different forms of water pools have been suggested: (i) free water which can be typically removed by gravity settling, (ii) interstitial water which is the water trapped between particles, within the flocculated slurry structure and within microbial cells, (iii) vicinal water which is water held tightly to sludge surfaces via hydrogen bonding, and (iv) chemically bound water (Vesilind 1994, Syed-Hassan, et al., 2017). Interstitial water, the vicinal water and chemical water is often denoted “bound water”. Bound water is correlated with the solid dry matter content after dewatering (Koop and Dichtl 2001). However, the measured amount of bound water depends on the measurement technique and is questionable (Waxelaire and Cèzac 2004). Further, the term bound water may be misleading as only a minor volume of water is bound; instead, the high water content may probably be a result of the high concentration of counterions and polymers that lowers the chemical potential of water in the flocs. A low chemical potential (low water activity) means that the osmotic pressure is high. The term “water-holding” water has been introduced for surface bound water, osmotic water and trapped water (Keiding et al 2001, Mikkelsen and Keiding 2002), but no consistent theory exists for distribution of water between organic particles, surfaces and bulk. Part of WP2 is to develop a consistent theory for water in organic suspensions. The project gives an unique opportunity to study distribution of water as both mechanical (WP2) and electroosmotic dewatering (WP 6) is used for water removal and HTC (WP4) is used to change the properties of the organic materials.

Dredging facilities and a belt filter will be installed at Lake Ormstrup to treat lake sediment and produce a filtrate that can be returned to the lake, and a dewatered P-rich sediment to be used as a fertilizer. The dewatered sediment from Lake Ormstrup might be used directly on the agricultural field, but due to a potential risk of too high cadmium concentrations, we will test our technologies for removal of these unwanted compounds. Different steps will be included to ensure the high quality of the filtrate as well as high dry matter content of the dewatered sediment. Today, synthetic polymers are used before separation for flocculation at WWTPs; however, synthetic polymers may be harmful to the environment.

Different biopolymer or filter aids will be tested as an alternative in collaboration with WP 8. There already exist several natural polymeric flocculants (biopolymers) containing mainly chitosan, modified chitosan or modified starch (cationic starch), which have been tested as less harmful substitutes to the synthetic polymers (Macczak et al 2020). However, most tests have been done on wastewater sludge and only rarely on lake sediment. Furthermore, the challenge with biopolymer for dewatering is the low molecular weight MW (or polymer length), poor water solubility, and inactive chemical properties (Pal et al 2021). Most research into the mechanisms underlying flocculation and its relationship to structural characteristics are only qualitative and more quantitative approaches are lacking, but important for the development of better biopolymers (Yang et al. 2016). Biopolymers are usually less effective than synthetic polymers, and it is difficult to predict flocculation efficiency from reported polymer characteristics such as molar mass, charge density, branching. The lower efficiency of biopolymers is probably due to a less flexible backbone. Most existing studies are purely empirical, and only few studies exist on the interaction between biopolymers and particles and how polymer properties affect flocculation. A fundamental study of polymer flocculation will be performed in WP2 including measurement and simulation of polymer diffusion and interaction with particles. A standard protocol will be developed for measuring and simulating polymer flexibility. Polymer flexibility will thereby be a new polymer characteristic required for polymer flocculant selection and for comparison of different types of biopolymers. It will be studied how chemicals, polymers and filter aids affect filtrate quality i.e. whether precipitation, adsorption and flocculation can be used to ensure low P, nitrogen, heavy metal and organic matter concentration in the filtrate.

As an alternative to the flocculation process, polymers and other chemicals may be omitted. A study combined hydrocyclone combined with membrane filtration and filter press for treatment of lake sediment to avoid the use of polymers (Kim et al 2015). Hydrocyclone is used to remove sand, and membrane to increase the dry matter content. A common problem in membrane filtration is clogging of the membrane, but new systems are developed e.g. vibrating membrane with high shear forces at the membrane surface thereby clogging problems can be reduced. Microfiltration membranes can remove all particles whereby no flocculation is required, which is attractive for the project to reduce contamination of the filtrate and the dewatered sediment. Vibrating membranes will be tested as a potential technology that can phase out the polymer or chemicals eventually combined with other microfiltration methods developed for high concentration suspensions. Sand particles may be harmful to the membrane. Lifetime of the membrane will therefore be quantified, and different pretreatment methods investigated if required. The possible maximum dry matter content after filtration will be found and the filtrate analyzed.

Methods will be developed to predict water content and stickiness of dewatered sludge to ensure that it is easy to handle the sediment after treatment. A theoretical understanding and model will be developed for the adsorbed, capillary and osmotic water in sediment, how it is affected by sediment characteristics and how it influences final dry matter content and stickiness of dewatered sediment.

Objectives

- Dewater lake sediment to dry matter content >15%

- Substitute synthetic flocculation polymers with biopolymers or filter aids.

- Produce filtrate that can be recycled to the lake (P << 1 ppm and N<< 10 ppm) or easily post-treated (WP3)

- Produce sediment that can be used as a fertilizer product (WP7), eventually, after post-treatment with II) electroosmotic method (WP6) or III) HTC (WP5)

Activity

Task 2.1: Establish and operate dewatering process at Lake Ormstrup

Laboratory facilities at Lake Ormstrup

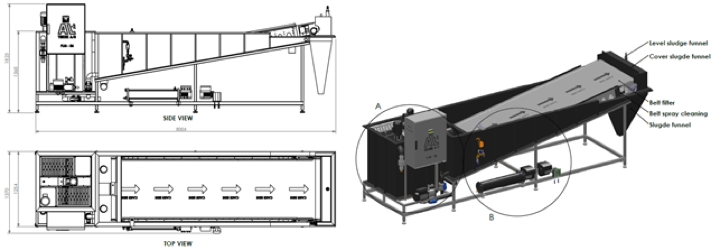

A belt filter apparatus (AL-2) with a capacity of 4 m3 sediment/h will be established at Lake Ormstrup in close collaboration with WP1 and DIS. With an expected final dry matter content of 15%, around 1.2-1.5 m3 of dry sediment will be produced per hour. The dry sediment will be tested directly as a fertilizer on the agricultural field or further treated (WP4-7). The rest, 1.2-1.5 m3 of filtrate will be produced and returned to the lake or further treated (WP3). Prior to dewatering, the sediment will be flocculated using 100-150 ml polymer/m3. The expected energy consumption is 0.5 kWh/m3 and the expected water consumption 100-200 L/m3. A cone bottom tank will be installed prior to the belt filter apparatus to remove heavy particles at the bottom and thereby reduce the consumption of flocculants. The volume of the tank will be designed so a hydraulic residence time of >20 min is obtained to reduce fluctuation of dry matter content at the feed to the belt filter apparatus. An on-line sensor for SS (suspended solid) will be installed and used to avoid overdosing with flocculant.

Figure 5: Belt filter from AL-2

Sediment will be tested regularly by measuring dry matter content, organic content, total P, total nitrogen, dissolved P, dissolved nitrogen, pH and conductivity.

Dewatered sediment will be characterized by measuring dry matter content, total P, total nitrogen and heavy metals. Filtrate will be characterized by measuring turbidity, total P, total nitrogen, dissolved P, dissolved nitrogen, heavy metals, pH and conductivity.

Success criteria: Dewatering equipment will be installed and up running after three month treating 4 m3 sediment/h dewatered to >15% dry matter content

Task 2.2: Test of polymers and filter aids for dewatering

At least two synthetic polymers and five or more biopolymers will be tested at full-scale. Tests will be done on-site. Dewatered sediment and filtrate will be tested as described in task 1. For each polymer, the optimal dosage will be determined using jar test, CST and analytical centrifugation test. Floc size will be quantified using light microscope and floc erosion and disruption will be quantified using floc strength test. At least two types of filter aids will be tested including one carbon based filter aid and a calcium mineral filter aid in close collaboration with WP5. Dewatered sediment and filtrate will be tested as described in task 1 and it will be studied how the addition of filter aids affects the HTC process (WP5).

Success criteria: At least one biopolymer or filter aid will be identified, which can substitute the synthetic organic polymer for sediment dewatering. The biopolymer, filter aid or a combination of the two will be implemented at the pilot-scale dewatering apparatus and it is possible to ensure a dewatered sediment with >15% dry matter content. The required doses (mass dose) of biopolymer will not exceed 20% of the required dose of synthetic polymer.

Task 2.3: Develop a procedure to measure and simulate polymer flexibility and flocculation efficiency

At least five synthetic polymers and five biopolymers (including both starch and chitosan-based polymers) will be tested. Polymers with varying length, charge density and backbone composition will be selected. Chitosan will be modified (amination, esterification) to vary the charge density of the flocculant. Viscosity will be measured at different ionic strength, pH and shear rate to characterize polymer length/width ratio and polymer flexibility (persistence length). Contact angle measurements are used to determine the surface tension of flocculant and sediment to calculate the intermolecular interaction energy during flocculation. Atomistic simulation will be used to calculate how polymer structure affects polymer diffusion and flexibility as a function of ionic strength. Optimal polymer dosage for sediment flocculation will be determined as described in task 2. Flocculation kinetics and floc size will be studied using a light microscope. Floc erosion and disruption will be quantified using floc strength test. Data for optimal dosage, floc size, floc strength, regrowth ability and kinetic will be correlated with polymer charge, length/width ratio and polymer flexibility. Methods to modify chitosan or starch to increase polymer length, flexibility and charge will be explored.

Success criteria: A standard protocol has been developed to quantify flocculant properties, including size, flexibility and interaction energy during flocculation. The floc strength after flocculation with biopolymers are improved with 20% (measured as the reduction of residual turbidity after shear treatment) by selecting or modifying biopolymers based on atomistic simulation and knowledge on how flocculant properties affect flocculation.

A new fundamental understanding of the flocculation process, polymer diffusion and interaction with particles will be delivered.

Task 2.4: Determine how pre-treatment with polymers and filter aids affects dewaterability and filtrate.

It will be studied how pH, pε, ionic strength affect the concentration of dissolved ions and organic molecules in sediment and filtrate. Chemical equilibrium programs e.g. Visual MineTEQ will be used to simulate the concentration of different ionic species and potential formation of minerals. Simulated data will be compared with experimental data. The result will be used to develop methods for the removal of P and heavy metals from the filtrate either by precipitation (ion species removal) or by coagulation (removal of small mineral particles). Fines in the water and the filtrate will be characterized (size, charge density) and the interaction between polymer flocculant/filter aids and fines studied and compared with theoretical simulations using the xDLVO theory. Hamaker constants for the xDLVO theory will be accessed by filtering fines, drying the filter, and measuring contact angle using three different solvents (cf. task 3).

Success criteria: Pretreatment of sediment prior to dewatering ensures that reject water (filtrate) can be returned directly to the lake, i.e. P content <0.5 ppm, nitrogen <5 ppm and concentration of heavy metals are below detection limit. Pretreatment of sediment prior to dewatering ensures that no further treatment is required before the concentration or adsorption of P and nitrogen in the filtrate. Pretreatment of sediment is optimized both for dewatering and the following treatment of dewatered sediment (electroosmotic dewatering, HTC) to reduce the overall use of chemicals.

Task 2.5: Concentration of sediment with vibrating membrane

A vibrating membrane will be installed and tested as a method to concentrate lake sediment without addition of polymers and other chemicals. Long-term experiment (>months) will be performed to investigate the potential degradation of the membrane i.e. as an effect of sand particles. After filtration, membranes will be analyzed with a light microscope and SEM. Different polymer microfiltration membranes will be used. For each membrane, filtrate quality, final dry matter and membrane damage will be analyzed. Different pretreatment methods will be tested to remove critical particles for solid removal, e.g., screening, use of hydrocyclones or prefiltration with cartridge filters.

If vibrating membranes cannot be used to concentrate lake sediment, other membrane types, e.g., ceramic membranes and other membrane set-up e.g. rotating disk filters will be tested. Alternatively, different methods to remove sand (such as e.g. hydrocyclones) might be introduced.

Success criteria: Lake sediment can be concentrated to >15% dry matter with vibrating membrane and no use of flocculant. No visible damages are observed on the used membrane after two months of operation.

Task 2.6: Develop thermogravimetric and hydro-textural methods to test lake sediment and predict final dry matter and handling after mechanical dewatering.

A thermogravimetric method will be developed to measure the critical moisture point (dry matter content where the drying rate starts to decline) as a function of humidity, sample volume and temperature. The measured critical moisture point will be compared with the final dry matter content after mechanical dewatering to develop an analytical procedure for the determination of the water-holding effect and predict final dry matter content after dewatering. The hydro-textural properties will be determined by measuring the water content at the transition between solid and plastic states (plastic limit) and the plastic and liquid states (liquid limit). The stickiness and rheological properties of the dewatered material will be measured and compared with water content and solid characteristics.

Success criteria: The maximum obtainable dry matter content after mechanical dewatering can be predicted within 10% by using thermogravimetric analysis. An easy-to-handle dewatered sediment sludge is obtained after dewatering. This should be non-sticky to facilitate pumping or transportation with an auger.

Task 2.7: Develop a theoretical model for the distribution of water in lake sediment

Water activity will be measured, and adsorption isotherms will be fitted to experimental data to calculate the I) amount of adsorbed water and II) “water holding” due to the osmotic pressure or capillary pressure. Water adsorption and water holding will be determined for dewatered sediment (both mechanical and electroosmotic dewatering) and HTC treated sediment. Experiments will be done at varying ionic strength and pH. A link between sediment characteristics, structure and distribution of water will be established. IR spectroscopy, pH titration or other relevant methods will be used to characterize the functional groups of the organic materials to link sediment characteristics to “water holding” in sediment.

Success criteria: A new fundamental understanding of the distribution of water (water holding) in organic suspension will be delivered. A theoretical model for the distribution of water will be developed that ensures that the maximum obtainable dry matter content after mechanical dewatering can be predicted from sediment characteristics.

Schedule

https://repairprojektet.dk/3742c5cb-a838-45bd-97fe-cab60766a420" alt="pastedGraphic_1.png" />

Milestones

Milestone 2.1: Suitable biopolymers for sediment treatment identified and introduced in the dewatering process

Milestone 2.2 Dewatering and compressibility study of lake sediment with >5 biopolymers and different organic and inorganic filter aids to ensure dry matter >15%.

Milestone 2.3: Dewatering protocol developed to ensure high filtrate quality

Milestone 2.4: Thermogravimetric method to predict final dry matter and rheological properties.

Milestone 2.5: Theoretical model for “water holding”.

WP structure

MLC will be the leader of WP2. The research in the WP will be completed by a PhD student (PhD1) hosted at AAU, supervised by MLC. The PhD student will focus on sediment dewatering and modelling of the process. Main workplace will be AAU Aalborg with periods at DIS in Stilling and AU Foulum. On the vibrating membrane technology an external stay of the PhD student will be planned e.g. at Mari Kallioinen’s Lab of separation and purification Lappeenranta University, Finland. A postdoc student (PostDoc1) will help establish and run the dewatering plan at Lake Ormstrup and test different types of synthetic and biopolymers in collaboration with the PhD in WP7 and DIS in WP1. Tests of different polymers and filter aids will be done partly at DIS facilities in Stilling and in close collaboration with WP3, WP4 and WP5 as the pre-treatment affects the composition of the filtrate and the dewatered sludge. Tests of hydro-textual properties of dewatered sediment will be done in close collaboration with WP6 to ensure that it is easy to handle dewatered sediment. Materials from WP3 and WP4 will be used for studying water-holding effects. HTC (WP4) is a method that change the organic materials and the collaboration between WP2 and WP4 is important for the study of water distribution and how material properties affect water distribution.

Path to commercialization

Flocculation and mechanical dewatering equipment are widely used, e.g., for sludge dewatering, manure treatment, and for several other applications. The required dewatering equipment is available, and several Danish companies exist (For example, AL-2, Hjortkjær and Stjernholm). If there is a market for sediment dewatering, it is expected that equipment can be delivered within a short period and the equipment will be tailored for sediment handling. Synthetic polymers are usually chosen for flocculation, but an important goal is to substitute the synthetic polymers with biopolymers. Biopolymers are produced today, but the required dosage is often high, increasing the cost. It is expected that companies that produce flocculants quickly can adapt to a new market for biopolymers including production of new biopolymers. Different types of biopolymers are already used in the food industry and there is a general interest in the substitution of synthetic polymers with biopolymers, e.g., in wastewater processes, if the cost is reasonable.

An alternative to the conventional process for dewatering is a process without using chemicals, e.g., hydrocyclone and vibrating membranes. In case, a promising method is developed, more steps are required prior to reaching commercialization. Innovation projects are required to develop membrane, scale-up systems and validate the technology. This will probably involve two or three companies including companies involved in the development of membranes and companies that build up membrane systems.

Risks associated with work package

The cost for using biopolymers is too high as the required biopolymer dosage is high, the suitable biopolymers are too expensive to produce or it is not possible to flocculate sediment with biopolymers. Preliminary laboratory-scale experiments have shown promising results with inexpensive biopolymers, therefore, the risk is low. Nonetheless, it still has to be documented that the biopolymer can be used for pilot- and commercial scale dewatering equipment where the shear forces are much stronger than in the laboratory. If it is not possible to substitute synthetic polymers with biopolymers we will: 1) use membrane technology where polymer are not required (Task 5), 2) use synthetic polymers and send the sediment to HTC process (WP5) where the polymers are degraded, or 3) send dredged sediment directly to the HTC process electroosmotic dewatering (WP 6) without initial dewatering

The filtrate is too polluted to be returned to the lake, and it is not possible to clean the water at site. A part of the project is development of water treatment concepts (WP 3) so it is expected that this risk is low, but the overall cost will increase if post-treatment is required. Alternative solution is to send filtrate for future treatment at the wastewater treatment plant.

The Results

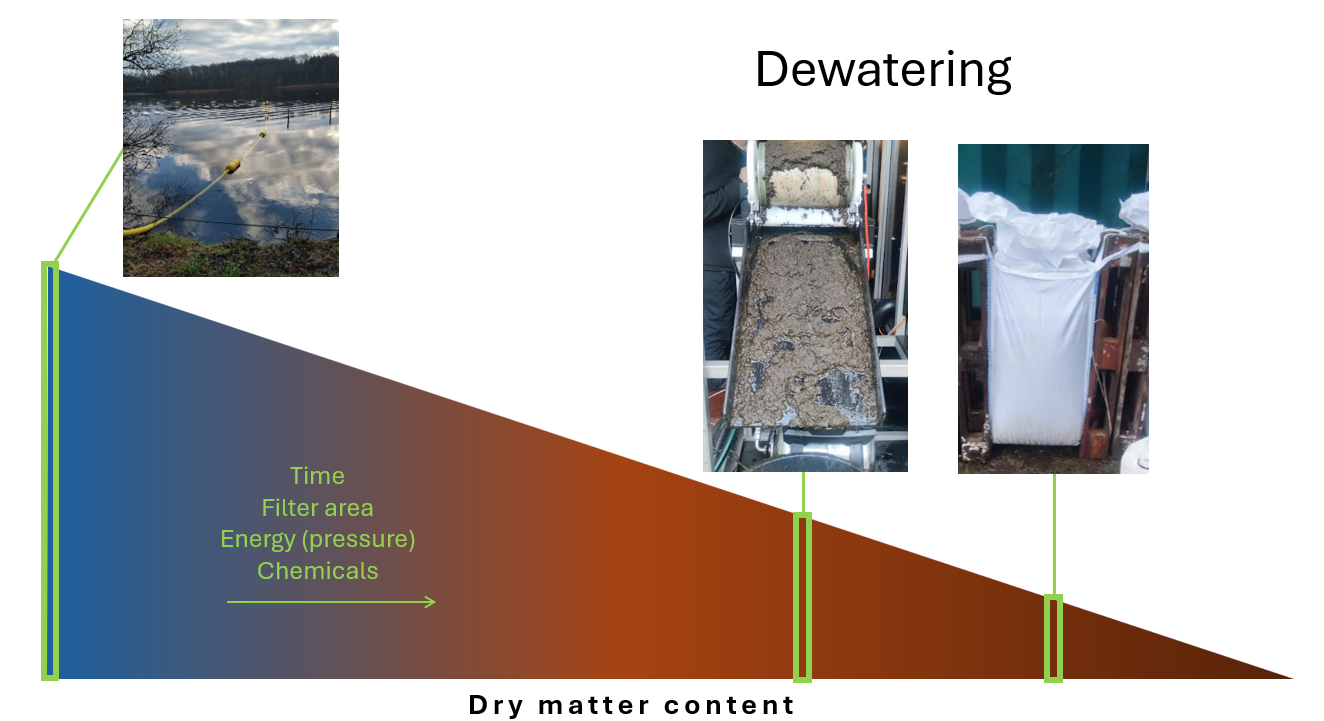

Dewatering of lake sediment

Lake sediment contains high amounts of water after dredging, and it is usually necessary to dewatered the sediment before further handling. Dry matter content depends on dewatering time, filtration areas (for filtration dewatering), energy input (pressure for filtration dewatering, and rotation speed for decanter centrifuges), and chemicals. Flocculants can be added to improve dewaterability, and has been an important part of the study

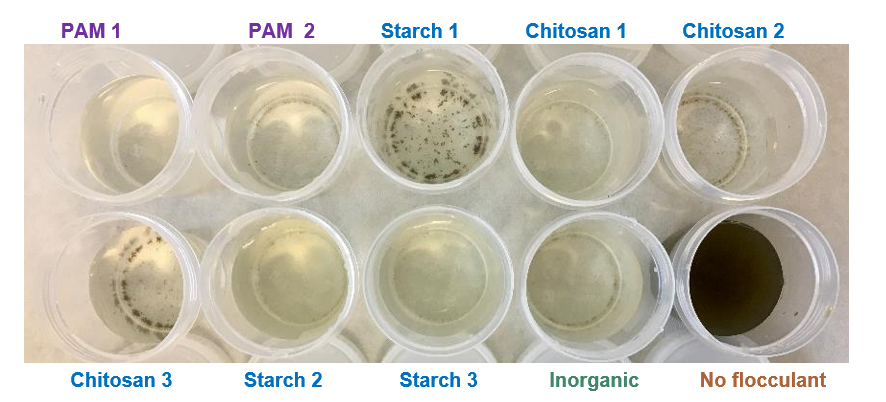

Different flocculants were tested e.g. polyacrylamide (PAM), modified starch, chitosan, polyaluminium (inorganic). Flocculations was required to ensure a clean water, that can be returned to the lake. The figure shows the filtrate water after filtration through a Geotube filter.

Comparison of synthetic and biopolymers for flocculation of lake sediment

Lake sediment can be considered as an alternative P source after its removal from eutrophic lakes. However, high water contents make sediment dewatering a crucial step towards the efficient reusability of remaining solids. The application of polymeric substances facilitates solid-liquid separation by flocculation of suspended particles. To lower the environmental risk of contamination with toxic, non-biodegradable monomeric residues during and after the application of synthetic polyacrylamide(PAM)-based polymers, switching to natural polymeric substances (biopolymers), e.g., starch- or chitosan-based, is increasingly emphasized. The dewatering performance of four conventional PAM-based polymers was compared to two starch- and one chitosan-based biopolymer. Laboratory experiments were conducted to determine the dewatering rate, floc size and strength, and reject water quality. Biopolymers generally caused the formation of smaller but less shear-sensitive flocs, and lower P levels in the reject water compared to synthetic polymers. Dewatering performance was correlated to the most important functioning influencing polymer-specific properties intrinsic viscosity (polymer extension) and surface charge density (CD). Due to the high CD and low intrinsic viscosity of the biopolymers, electrostatic patch flocculation seems to be the favored flocculation mechanism, while for synthetic polymers bridging seems to be dominating. Solid-liquid separation technologies should be adjusted to the resulting floc size and structure, while surface CD and intrinsic viscosity are important properties for the choice of biopolymer. Overall, biopolymers can function as a more environmentally friendly alternative to synthetic products for lake sediment dewatering accompanied by the potential for P recovery.

For more information:

Haasler S, Christensen, ML, Reitzel K. (2023). Synthetic and biopolymers for lake restoration – an evaluation of flocculation mechanism and dewatering performance. Journal of Environmental Management 331, 117199

Mixing is critical when biopolymers is used as flocculant

The flocculation mechanism in lake sediment was studied using biobased flocculants (chitosan) and synthetic flocculants (polyacrylamide), both individually and in combination. The test was done in a pipe flow mixing system. Chitosan is cationic polysaccharide with a high charge density, allowing for rapid charge neutralization and forming compact flocs. However, its flocs are fragile due to the dominance of patching mechanisms. Conversely, polyacrylamide form stronger flocs via bridging mechanisms but required either prolonged low-shear mixing or short-duration high-shear mixing to achieve optimal performance. Dual flocculants leveraged the strengths of both components, resulting larger and more robust flocs while reducing the requiring dosage (0.56 mg/g of chitosan and 0.28 mg/g of polyacrylamide). In contrast, the use of single flocculants needed higher doses, with chitosan and polyacrylamide requiring 0.84 mg/g and 1.12 mg/g, respectively. Further, this approach reduced residual turbidity and enhanced sediment dewatering without requiring post-aging. size in the sediment is important for the optimal flocculant dosing, as smaller particles required higher chitosan concentrations for effective flocculation. The pipe flow mixing method minimized floc breakage, enhanced flocculation efficiency, and facilitated subsequent liquid-solid separation processes. Combining bio- and synthetic flocculants offered an environmentally friendly and cost-effective solution, reducing both flocculant dosage and energy consumption compared to single flocculant approaches.

Will soon be published.

First pilot-plant test at the lake

A pilot-scale belt filter and flexible intermediate bulk containers (FIBC) were used for dewatering lake sediment with the sediment treated with a synthetic polymer or three different biopolymers (chitosan and modified starch). The goal of the study was to retain the phosphorus in the filter cake while returning the filtrate to the lake with a minimal phosphorus content. Results showed dry matter content of up to 16 % in the dewatered sediment and the sediment retained 96–99 % of the phosphorus. Furthermore, nitrogen was reduced by 27–71 % in the filtrate water. Toxicity test found low ecotoxicity for most biopolymer filtrates, whereas synthetic polymer showed the highest potential ecotoxicity. Consequently, biopolymers provided satisfactory results, proving more environmentally friendly despite requiring longer filtration time.

For more information:

Simoni G., Cheali P. Roslev P, Haasler S, Reitzel K., Smith AM., Haferbier MHS, Christensen ML (2024) Flocculating and dewatering of lake sediment: An in-situ pilot study comparing synthetic polymers and biopolymers for restoring lake water quality and reusing phosphorus. Science of the Total Environment, 913, 169597.

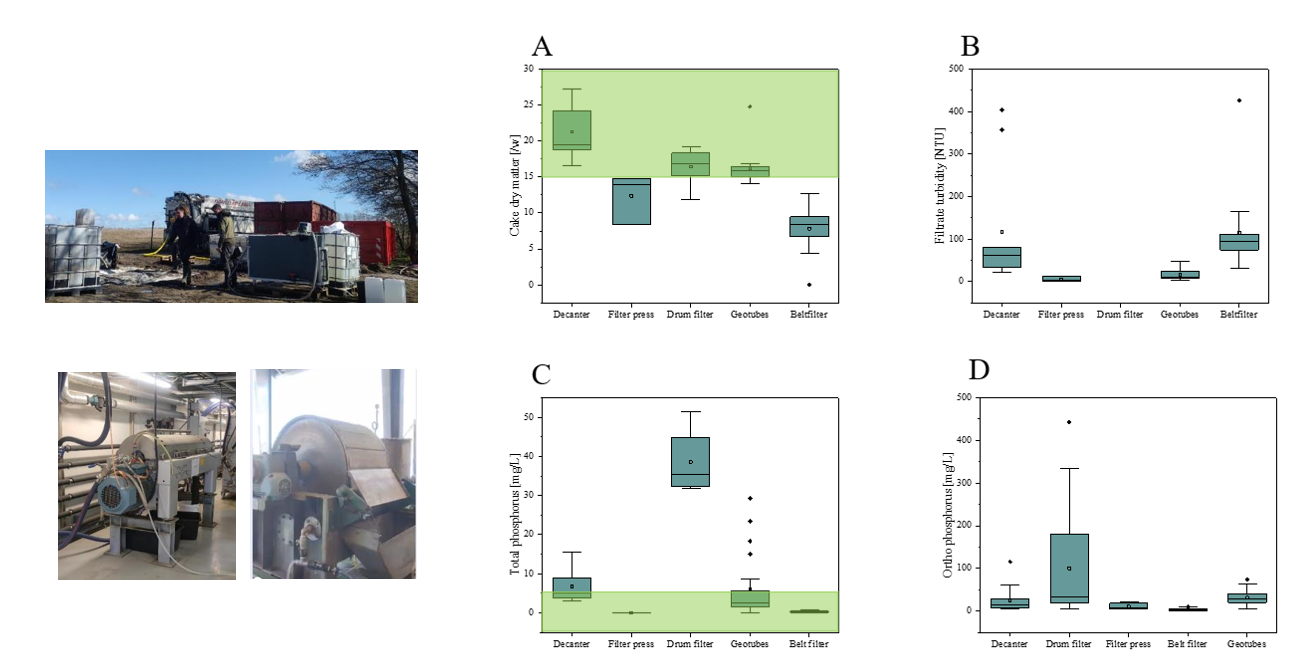

Comparison of different dewatering technologies

Flocculation prior to dewatering in a Geotube or decanter centrifuge use improved filtrate clarity. Additionally, flocculation was essential for the effective operation of the plate and frame filter press and vacuum drum filter. The plate and frame filter press produced the lowest total phosphorus (TP) content (6–23 µg/L) and turbidity (0.87 NTU) in the filtrate, indicating superior quality, especially with biobased polymeric flocculants. Decanter centrifuges achieved the highest dry matter (DM) content (22.5 %) but required starch as a flocculant to improve filtrate quality. Conversely, the drum filter performed less effectively, likely due to elevated TP levels in the filtrate caused by its coarser mesh size.

This study demonstrates the potential of bio-based flocculants for enhancing sediment dewatering and phosphorus removal. The findings underscore the value of bioflocculants, particularly in low-shear processes, as a sustainable solution for lake restoration. Further research should explore scale-up possibilities and optimize conditions to maximize bio-based flocculant performance in practical applications.

For more information:

Simoni G., Smith AM., Cheali P., Chen X., Naknikham U., Christensen ML (2025) Comparison of solid-liquid separation technologies for dewatering of lake sediment flocculated with biobased flocculants. Total Environment Engineering. 2, 100004.